The advent of 3D printing has ushered in a new era of innovation, transforming the fields of manufacturing and design in ways that were once thought impossible. What was once the domain of futuristic speculation has become a tangible, disruptive force across various industries. This article delves into how 3D printing is revolutionizing manufacturing and design, exploring its applications, benefits, and the profound impact it’s having on the global economy.

What is 3D Printing?

3D printing, also known as additive manufacturing, is the process of creating three-dimensional objects by layering material based on a digital model. Unlike traditional manufacturing methods, which often involve subtracting material (such as cutting or drilling), 3D printing builds objects layer by layer from the ground up. This process allows for intricate designs, customization, and the creation of complex geometries that would be difficult or impossible to achieve with conventional manufacturing techniques.

The materials used in 3D printing are diverse, ranging from plastics and resins to metals, ceramics, and even biological substances. This versatility makes 3D printing applicable to a wide range of industries, from aerospace and automotive to healthcare, fashion, and beyond.

The Rise of 3D Printing in Manufacturing

The integration of 3D printing into manufacturing processes has had a transformative impact, leading to significant advancements in production efficiency, cost reduction, and product innovation.

- Rapid Prototyping

- Accelerating Design Iteration: One of the earliest and most widespread applications of 3D printing in manufacturing is rapid prototyping. Designers and engineers can quickly produce prototypes of new products, allowing for rapid iteration and refinement. This accelerates the development process, enabling companies to bring products to market faster than ever before.

- Cost-Effective Prototyping: Traditional prototyping methods can be expensive and time-consuming, particularly when multiple iterations are required. 3D printing reduces the cost and time associated with prototyping by eliminating the need for specialized tooling and molds, allowing for on-demand production of prototypes.

- Custom Manufacturing

- Personalization at Scale: 3D printing allows for mass customization, enabling manufacturers to produce unique, tailored products on a large scale. This is particularly valuable in industries such as healthcare, where customized medical devices, implants, and prosthetics can be produced to meet the specific needs of individual patients.

- Flexible Production: With 3D printing, manufacturers can easily adapt to changing customer demands and market trends. The ability to quickly modify designs and produce small batches of customized products gives companies a competitive edge in a rapidly evolving marketplace.

- Complex Geometries and Lightweight Structures

- Innovative Design Capabilities: 3D printing enables the creation of complex geometries that would be impossible or extremely difficult to achieve with traditional manufacturing methods. This includes intricate lattice structures, organic shapes, and internal channels, which can enhance the functionality and aesthetics of a product.

- Lightweighting: In industries such as aerospace and automotive, reducing the weight of components is critical for improving fuel efficiency and performance. 3D printing allows for the design of lightweight structures with optimized strength-to-weight ratios, leading to more efficient and sustainable products.

- On-Demand Manufacturing and Supply Chain Optimization

- Reducing Inventory Costs: 3D printing supports on-demand manufacturing, allowing companies to produce parts and products as needed, rather than maintaining large inventories. This reduces storage costs, minimizes waste, and allows for greater flexibility in responding to market fluctuations.

- Streamlining Supply Chains: By enabling localized production, 3D printing reduces the need for long supply chains and complex logistics. Companies can produce parts closer to where they are needed, reducing lead times and transportation costs.

- Sustainability and Waste Reduction

- Eco-Friendly Production: 3D printing is inherently more sustainable than traditional manufacturing methods, as it generates less waste. Material is only used where it is needed, reducing the amount of excess material that ends up as waste. Additionally, many 3D printing materials are recyclable, further contributing to environmental sustainability.

- Efficient Resource Use: 3D printing allows for more efficient use of resources by optimizing material usage and energy consumption. This makes it an attractive option for companies looking to reduce their environmental footprint and meet sustainability goals.

Applications of 3D Printing Across Industries

The impact of 3D printing extends across a wide range of industries, each benefiting from the unique capabilities of this technology.

- Aerospace and Defense

- Lightweight Components: In the aerospace industry, 3D printing is used to produce lightweight, high-performance components that can withstand extreme conditions. This includes everything from engine parts to structural components, helping to improve fuel efficiency and reduce emissions.

- Rapid Spare Part Production: 3D printing enables the on-demand production of spare parts, reducing the need for large inventories and long lead times. This is particularly valuable in the defense industry, where the ability to quickly produce replacement parts can be critical to mission success.

- Healthcare

- Customized Medical Devices: 3D printing is revolutionizing healthcare by enabling the production of customized medical devices, such as implants, prosthetics, and dental appliances. These devices can be tailored to the specific needs of individual patients, improving comfort, functionality, and outcomes.

- Bioprinting: One of the most exciting developments in 3D printing is bioprinting, where living cells are printed to create tissues and organs. While still in the early stages of development, bioprinting holds the potential to revolutionize organ transplantation and regenerative medicine.

- Automotive

- Prototyping and Tooling: The automotive industry has embraced 3D printing for rapid prototyping and the production of custom tools and fixtures. This allows manufacturers to accelerate the development of new vehicles and improve the efficiency of production lines.

- Customization and Spare Parts: 3D printing is also used for the production of custom vehicle components and spare parts. This allows for greater personalization and reduces the need for large inventories of replacement parts.

- Fashion and Jewelry

- Custom and Intricate Designs: The fashion and jewelry industries are leveraging 3D printing to create custom, intricate designs that would be difficult or impossible to produce with traditional methods. This includes everything from custom-fit clothing and shoes to intricate jewelry pieces.

- Sustainable Fashion: 3D printing is also contributing to the rise of sustainable fashion by enabling the production of clothing and accessories with minimal waste. Designers can create on-demand, made-to-order pieces that reduce the environmental impact of fashion production.

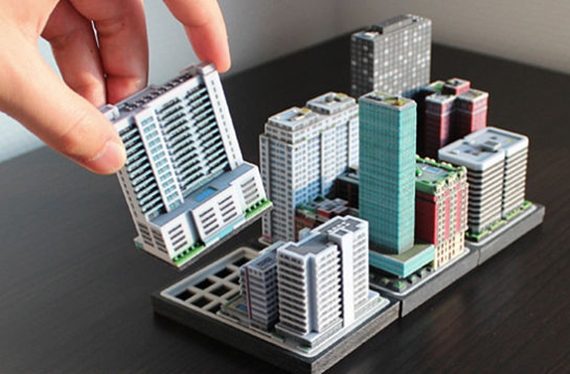

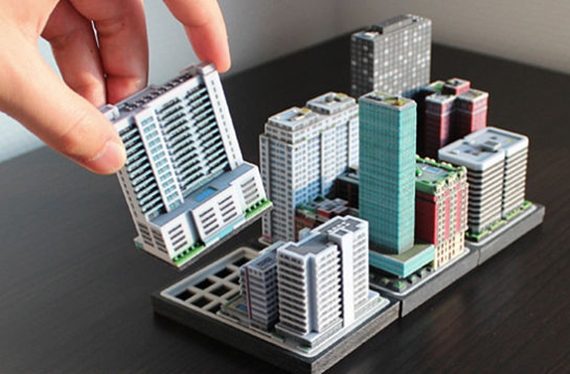

- Architecture and Construction

- Innovative Building Techniques: In architecture and construction, 3D printing is being used to create innovative building materials and structures. This includes everything from 3D-printed concrete components to entire buildings, offering new possibilities for sustainable and efficient construction.

- Customized Interiors: 3D printing is also being used to create customized interior elements, such as furniture, lighting fixtures, and decorative features. This allows architects and designers to bring their creative visions to life with greater precision and flexibility.

Challenges and Considerations

While 3D printing offers numerous advantages, it is not without its challenges. These include:

- Material Limitations

- While the range of materials available for 3D printing is expanding, there are still limitations in terms of material properties, such as strength, durability, and heat resistance. These limitations can restrict the use of 3D printing in certain applications, particularly those requiring high-performance materials.

- Quality Control

- Ensuring consistent quality in 3D-printed parts can be challenging, particularly for complex geometries and large-scale production. Variations in material properties, printing conditions, and post-processing techniques can impact the final product’s performance and appearance.

- Cost and Accessibility

- While 3D printing can be cost-effective for prototyping and small-scale production, the cost of high-quality 3D printers and materials can still be prohibitive for some companies. Additionally, the technology and expertise required for 3D printing may not be readily available in all regions.

- Intellectual Property Concerns

- The ease of replicating designs with 3D printing raises concerns about intellectual property theft and counterfeiting. Companies must take steps to protect their designs and ensure that 3D printing technology is used responsibly.

The Future of 3D Printing in Manufacturing and Design

The future of 3D printing in manufacturing and design is bright, with continued advancements in technology, materials, and applications driving the industry forward. Some key trends to watch include:

- Expansion of Material Options

- As research and development in 3D printing materials continue, we can expect to see an even wider range of materials with improved properties. This will open up new possibilities for 3D printing in industries such as aerospace, healthcare, and consumer electronics.

- Integration with Other Technologies

- The integration of 3D printing with other emerging technologies, such as artificial intelligence (AI), robotics, and the Internet of Things (IoT), will enhance the capabilities of 3D printing and enable more sophisticated manufacturing processes. For example, AI-driven 3D printers could optimize designs in real-time, while IoT-connected printers could enable automated production and supply chain management.

- Increased Adoption in Consumer Markets

- As 3D printing becomes more accessible and affordable, we can expect to see increased adoption in consumer markets. This could include everything from personalized consumer electronics and home goods to custom fashion and jewelry. The ability to create unique, made-to-order products will appeal to consumers looking for one-of-a-kind items.

- Sustainability and Circular Economy

- 3D printing will play a crucial role in the transition to a circular economy, where products are designed for reuse, recycling, and minimal waste. The ability to produce only what is needed, when it is needed, will reduce waste and conserve resources, contributing to more sustainable manufacturing practices.

- Large-Scale and Advanced Manufacturing

- The development of large-scale 3D printers and advanced manufacturing techniques will enable the production of bigger and more complex structures, such as buildings, aircraft components, and industrial machinery. This will further expand the scope of 3D printing in industries like construction, aerospace, and energy.

Conclusion

3D printing is revolutionizing manufacturing and design, offering unprecedented opportunities for innovation, customization, and efficiency. As the technology continues to evolve, its impact on various industries will only grow, leading to new possibilities and challenges. Companies that embrace 3D printing and integrate it into their operations will be well-positioned to lead the way in this exciting new era of manufacturing and design.